Detailed Fire Modeling (Task 11)

Contents

- 1 Task Overview

- 2 Related Element of ASME/ANS PRA Standard

- 3 Related EPRI 1011989 NUREG/CR-6850 Appendices

- 4 Fire Modeling Tools

- 5 Ignition Source Specific Fire Modeling Guidance

- 6 Recommended HRR Values for Electrical Fires

- 7 Additional Fire Modeling Considerations

- 8 Fire Propagation and Suppression Guidance

Task Overview

Background

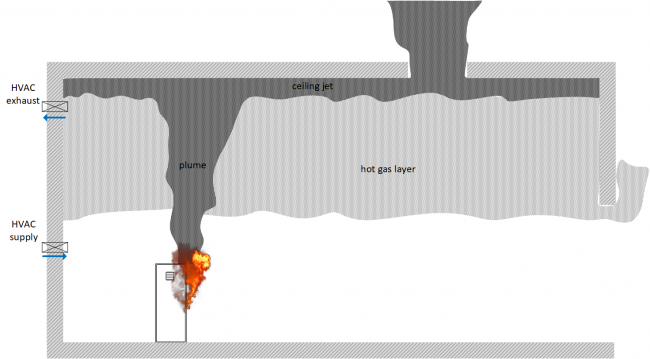

This task describes the method to examine the consequences of a fire. This includes consideration of scenarios involving single compartments, multiple fire compartments, and the main control room. Factors considered include initial fire characteristics, fire growth in a fire compartment or across fire compartments, detection and suppression, electrical raceway fire barrier systems, and damage from heat and smoke. Special consideration is given to turbine generator (T/G) fires, hydrogen fires, high-energy arcing faults, cable fires, and main control board (MCB) fires. There are considerable improvements in the method for this task over the EPRI FIVE and the Fire PRA Implementation Guide in nearly all technical areas.

Purpose

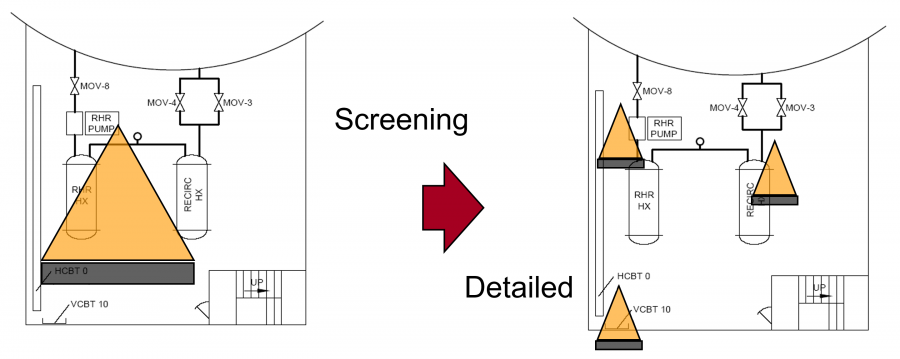

In the preceding tasks, the analyses were organized around compartments, assuming that a fire would have widespread impact within the compartment. In Task 11, for those compartments found to be potentially risk-significant (i.e., unscreened compartments), a detailed analysis approach is provided. As part of the detailed analysis, fire growth and propagation is modeled and possibility of fire suppression before damage to a specific target set is analyzed.

The detailed fire modeling process generally follows a common step structure, but the details of the analyses often vary depending on the specifics of the postulated fire scenario. This task provides separate procedures for three general categories of fire scenarios: fires affecting target sets located inside one compartment (discussed in Section 11.5.1); fires affecting the main control room (MCR; Section 11.5.2); and fires affecting target sets located in more than one fire compartment (multicompartment fire analysis; Section 11.5.3).

Task 11 provides final estimates for the frequency of occurrence of fire scenarios involving a specific fire ignition source failing a predefined target set before fire protection succeeds in protecting the target set. This result is combined in the final quantification steps that follow this task, with the CCDP/CLERP given failure of the target set to estimate the CDF/LERF contribution for each fire scenario. The CCDP/CLERP may include modified human error probabilities based on fire scenario specifics.

Scope

Detailed fire modeling encompasses an analysis of the physical fire behavior (i.e., fire growth and propagation analysis), equipment damage, fire detection, and fire suppression. The fire scenarios to analyze as part of this detailed analysis task are divided into three categories:

- General single compartment fire scenarios. This general category covers fire scenarios damaging target sets located within the same compartment, exclusive of those scenarios within or impacting the MCR. In general, in this category, the fire ignition source is in the same compartment as the target set. The majority of fire scenarios analyzed generally falls into this category. The procedures applicable to the analysis of these fire scenarios are presented in Section 11.5.1.

- MCR fire scenarios. This general category covers all fires that occur within the MCR. This category also covers scenarios involving fires in compartments other than the MCR that may force MCR abandonment. The MCR analysis procedures are presented in Section 11.5.2.

- Multicompartment fire scenarios: This general category covers all fire scenarios where it is postulated that a fire may spread from one compartment to another and damage target elements in multiple compartments. In this category of scenarios, damaging effects of a fire (e.g., heat) are assumed to spread beyond the compartment of fire origin. The multicompartment fire analysis procedures are presented in Section 11.5.3.

A detailed fire modeling analysis is performed for each fire scenario in each unscreened fire compartment. For many compartments, it may be appropriate to develop several fire scenarios to appropriately represent the range of unscreened fire ignition sources (i.e., scenarios that would not screen out in Task 8) that might contribute to the fire risk. Detailed fire modeling may utilize a range of tools to assess fire growth and damage behavior, and the fire detection and suppression response, for specific fire scenarios.

The ultimate output of Task 11 is a set of fire scenarios, frequency of occurrence of those scenarios, and a list of target sets (in terms of fire PRA components) associated with the scenarios. For scenarios involving the MCR, the possibility of forced abandonment is also noted. Note that a fire scenario represents a specific chain of events starting with ignition of a fire ignition source, propagation of the fire effects to other items, and possibility of damaging a set of items identified as target set before successful fire suppression.

Related Element of ASME/ANS PRA Standard

Fire Scenario Selection (FSS)

Related EPRI 1011989 NUREG/CR-6850 Appendices

Appendix E, Appendix for Chapters 8 and 11, Severity Factors

Appendix F, Appendix for Chapter 8, Walkdown Forms

Appendix G, Appendix for Chapters 8 and 11, Heat Release Rates

Appendix H, Appendix for Chapters 8 and 11, Damage Criteria

Appendix L, Appendix for Chapter 11, Main Control Board Fires

Appendix M, Appendix for Chapter 11, High Energy Arcing Faults

Appendix N, Appendix for Chapter 11, Hydrogen Fires

Appendix O, Appendix for Chapter 11, Turbine Generator Fires

Appendix P, Appendix for Chapter 11, Detection And Suppression Analysis

Appendix Q, Appendix for Chapter 11, Passive Fire Protection Features

Appendix R, Appendix for Chapter 11, Cable Fires

Appendix S, Appendix for Chapter 11, Fire Propagation To Adjacent Cabinets

Appendix T, Appendix for Chapter 11, Smoke Damage

Fire Modeling Tools

Fire modeling tools include a range of complexity, from Excel-based tools which rely on physics-based algebraic relationships such as EPRI FIVE and the FDTs, to moderately complex tools such as CFAST's two-zone computational model, up to the most complex (and computationally-demanding) finite element analysis tools such as FDS.

Fire Model Verification and Validation

NUREG-1824 EPRI 1011999 documents the verification and validation (V&V) of five fire models that are commonly used in NPP applications. The models in the V&V report include:

- NRC's NUREG-1805 Revision 1

- EPRI's Fire-Induced Vulnerability Evaluation Revision 1 (FIVE-REV 1)

- National Institute of Standards and Technology's (NIST) Consolidated Model of Fire Growth and Smoke Transport (CFAST) Version 5

- NIST's Fire Dynamics Simulator (FDS) Version 4

- Electricite de France's (EdF) MAGIC Version 4.1.1

NUREG-1824 Supplement 1 EPRI 3002002182 updates the original NUREG-1824 / EPRI 1011999 report with additional experiments and uses the latest versions of the fire modeling software available at the time of publication. The models in the V&V report include:

- NRC's Fire Dynamics Tools (FDTs Version 1805.1)

- EPRI's Fire-Induced Vulnerability Evaluation (FIVE Rev. 2)

- NIST's CFAST Version 7.0.0

- EdF's MAGIC Version 4.1.3

- NIST's FDS Version 6.2.0

Fire Models Included in V&V Guidance

NRC Fire Dynamics Tools - NUREG-1805

EdF's MAGIC is available through EPRI for EPRI members

Fire Model User's Guide

NUREG-1934 EPRI 1023259 provides guidance on the proper application of fire models to nuclear power plant fire scenarios. Eight (8) different example fire scenarios are developed and discussed in this report.

Ignition Source Specific Fire Modeling Guidance

| Bin | Plant Location | Ignition Source | Fire Modeling Guidance | Fire Modeling Reference |

|---|---|---|---|---|

| 1 | Battery Room | Batteries | Use HRR distribution for Electric Motors (Case 7 of Table G-1) | EPRI 1011989 / NUREG/CR-6850 |

| 2 | Containment (PWR) | Reactor Coolant Pump | For electrical fires: Pumps (electrical fires) HRR Distribution (Case 6 of Table G-1)

For oil fires: See Section G.4 of NUREG/CR-6850 for HRR for flammable liquid fires. EPRI 3002005303, although not formally reviewed by the NRC, provides a method to more realistically characterize the HRR profile and duration for liquid spill fires. |

EPRI 1011989 / NUREG/CR-6850 |

| 3 | Containment (PWR) | Transients and Hotwork | Prior Guidance

For HRR: Transient Combustible HRR Distribution (Case 8 of Table G-1) While NUREG/CR-6850 (EPRI 1011989) provides a value for a default transient fire heat release rate (HRR) distribution and guidance for addressing plant specific locations not bounded by the default HRR, it does not provide guidance on the use of a lower HRR for plant specific locations where the lower HRR can be justified. See the methods panel links for additional information on using HRRs other than the one prescribed in NUREG/CR-6850 Table G-1. For transient growth rates: See Section 17 of Supplement 1 (FAQ 08-0052)

New Guidance (2019/2020) EPRI 3002015997 provides the results of a study to develop experimental data for transient fire sizes. The results from the testing effort served as a primary input to develop more realistic data to analyze transient fire risk. EPRI 3002016054 develops new distributions of peak heat release rate, total energy release, and zones of influence for transient fires. Additionally, EPRI 3002016054 recommends input values for the detailed fire modeling of transient fires that include fire growth and decay parameters, yields of minor products of combustion, heat of combustion, and the physical size and effective elevation of the fire. |

EPRI 1011989 / NUREG/CR-6850

Methods Panel Review Decisions FAQ 08-0052, Section 17 of Supplement 1 Panel Decision (NRC Recent Fire PRA Methods Review Panel Decisions - Attachment 3) |

| 4 | Control Room | Main Control Board | NUREG-2178 Volume 1 / EPRI 3002005578 provides updated HRR distribution(s) for the main control board based on control cabinet size (either Function Group 4a (Large Enclosures) or Group 4b (Medium Enclosures).

Appendix L of NUREG/CR-6850 provides a statistical model for estimating the conditional probability of damage to a set of target items inside the main control board. NUREG-2178 Volume 2 / EPRI 3002016052 Section 7 provides an alternative to the method described in Appendix L of NUREG/CR-6850 for evaluating the risk of fire events originating in the MCB, whereby MCB fire scenarios are modeled as a progression of damage states using an event tree model. In this formulation, each damage state requires the definition of a target set, which consists of one or more MCB functions that can be damaged by fire. The functions within the scope of this analysis are those that are represented with basic events in the plant response model and supported with cables routed within the MCB. The alternative model described in this guidance explicitly incorporates two characteristics of MCB fires observed in operating experience—relatively small fires in low-voltage panels and the ability for prompt detection and suppression by control room operators. Operating experience suggests that the majority of fires in the MCB are limited to a single subcomponent or group of subcomponents near the point of ignition. In addition, these fires are promptly detected and suppressed by control room operators. Therefore, the event tree model explicitly accounts for the operator’s ability to quickly detect and suppress the fire before growth and/or propagation. |

NUREG-2178 Vol 1 / EPRI 3002005578 |

| 5 | Control/Aux/Reactor Building | Cable fires caused by welding and cutting | FAQ 13-0005 provides additional guidance for detailed fire modeling on both self-ignited cable fires and cable fires caused by welding and cutting. This FAQ outlines a more realistic approach for addressing these types of fires in cable trays and suggests replacement text for Section R.1 of NUREG/CR-6850. However, the current method of evaluating cable fire risk in NUREG/CR-6850 remains an acceptable approach. | EPRI 1011989 / NUREG/CR-6850 |

| 6 | Control/Aux/Reactor Building | Transient fires caused by welding and cutting | (See Bin 3) | (See Bin 3) |

| 7 | Control/Aux/Reactor Building | Transients | (See Bin 3) | (See Bin 3) |

| 8 | Diesel Generator Room | Diesel Generators | For electrical fires: Use HRR distribution for Electric Motors (Case 7 of Table G-1)

For oil fires: See Section G.4 of NUREG/CR-6850 for HRR for flammable liquid fires. EPRI 3002005303, although not formally reviewed by the NRC, provides a method to more realistically characterize the HRR profile and duration for liquid spill fires. |

EPRI 1011989 / NUREG/CR-6850 |

| 9 | Plant-Wide Components | Air Compressors | For electrical fires: Use HRR distribution for Electric Motors (Case 7 of Table G-1)

For oil fires: See Section G.4 of NUREG/CR-6850 for HRR for flammable liquid fires. EPRI 3002005303, although not formally reviewed by the NRC, provides a method to more realistically characterize the HRR profile and duration for liquid spill fires. |

EPRI 1011989 / NUREG/CR-6850 |

| 10 | Plant-Wide Components | Battery Chargers | HRR Distribution for Classification Group 2, MCCs and Battery Chargers | NUREG-2178 Vol 1 / EPRI 3002005578 |

| 11 | Plant-Wide Components | Cable fires caused by welding and cutting | FAQ 13-0005 provides additional guidance for detailed fire modeling on both self-ignited cable fires and cable fires caused by welding and cutting. This FAQ outlines a more realistic approach for addressing these types of fires in cable trays and suggests replacement text for Section R.1 of NUREG/CR-6850. However, the current method of evaluating cable fire risk in NUREG/CR-6850 remains an acceptable approach. | EPRI 1011989 / NUREG/CR-6850 |

| 12 | Plant-Wide Components | Cable Run (self-ignited cable fires) | FAQ 13-0005 provides additional guidance for detailed fire modeling on both self-ignited cable fires and cable fires caused by welding and cutting. This FAQ outlines a more realistic approach for addressing these types of fires in cable trays and suggests replacement text for Section R.1 of NUREG/CR-6850. However, the current method of evaluating cable fire risk in NUREG/CR-6850 remains an acceptable approach. | EPRI 1011989 / NUREG/CR-6850 |

| 13 | Plant-Wide Components | Dryers | Transient Combustible HRR Distribution (Case 8 of Table G-1) | EPRI 1011989 / NUREG/CR-6850 |

| 14 | Plant-Wide Components | Electric Motors | NUREG-2178 Volume 2 / EPRI 3002016052 provides updated HRR distributions for electrical motors (compared with the original distributions from NUREG-6850). | NUREG-2178 Vol 2 / EPRI 3002016052 |

| 15 | Plant-Wide Components | Electrical Cabinets | Propagation: FAQ 08-0042 (Section 8 of Supplement 1) clarifies the treatment of fire spread beyond the ignition source for unvented cabinets.

Propagation for Well-Sealed MCCs Greater Than 440V: FAQ 14-0009 provides clarification for the treatment of fire propagation from well-sealed MCCs operating at greater than 440V. Heat Release Rates: NUREG-2178 Volume 1 / EPRI 3002005578 provides updated heat release distributions for electrical enclosures. The analyst should review the equipment function or size to determine an appropriate heat release rate distribution provided in Table 7-1. Heat release rates for electrical cabinets are also found in Table G-1 of EPRI 1011989 / NUREG/CR-6850. Fire location: FAQ 08-0043 clarifies the treatment of fire location in electrical cabinets. Fire diameter: NUREG-2178 Volume 1 / EPRI 3002005578 Section 4.2 provides guidance on the selection of an appropriate fire diameter. Fire plume modeling (obstructed plume): NUREG-2178 Volume 1 / EPRI 3002005578 Section 6 provides a method to account for the impact of the enclosure on the vertical thermal zone of influence above the enclosure during a fire. A summary of the obstructed plume methodology and the results can be found here. NUREG-2178 Volume 2 / EPRI 3002016052 describes improved methods intended to increase the realism in the modeling of selected ignition sources by investigating the treatment of flame radiation and obstructed radiation, fire propagation between adjacent electrical cabinets, and HRRs for electric fire location factor, and the modeling of the main control board. NUREG-2230 / EPRI 3002016051 significantly improves the realism of modeling electrical cabinet fires, presenting a revised set of parameters that addresses both the fire growth and the suppression response. The set of electrical cabinet fire events was classified into either a growing or interruptible fire categorization. Interruptible fires are those that have observed ignition but no significant growth for a period of time. Growing fires, on the other hand, experience growth immediately after ignition. Furthermore, the detection-suppression event tree has been updated to better allow for early plant personnel suppression actions. Additional manual non-suppression bins have been added to better reflect the scenario characteristics. |

EPRI 1011989 / NUREG/CR-6850

FAQ 08-0042, Section 8 of Supplement 1 NUREG-2178 Vol 1 / EPRI 3002005578 |

| 16.a | Plant-Wide Components | High Energy Arcing Faults - Low Voltage Electrical Cabinets (480-1000 V) | Appendix M (M.4.2) provides an empirical model for determination of the ZOI from HEAFsHigh Energy Arching Faults (HEAFs).

Additional research is on-going (HEAF Research). |

EPRI 1011989 / NUREG/CR-6850 |

| 16.b | Plant-Wide Components | High Energy Arcing Faults - Medium Voltage Electrical Cabinets (>1000 V) | Appendix M (M.4.2) provides an empirical model for determination of the ZOI from HEAFs.

Additional research is on-going (HEAF Research). |

EPRI 1011989 / NUREG/CR-6850 |

| 16.1 | Plant-Wide Components | HEAF for segmented bus ducts | Section 7.2.1.5 of Supplement 1 (FAQ 07-0035) provides an empirical model for estimating the ZOI for segmented bus duct fires.

Additional research is on-going (HEAF Research). |

FAQ 07-0035, Section 7 of Supplement 1 |

| 16.2 | Plant-Wide Components | HEAF for iso-phase bus ducts | Section 7.2.1.5 of Supplement 1 (FAQ 07-0035) provides an empirical model for estimating the ZOI for iso-phase duct fires.

Additional research is on-going (HEAF Research). |

FAQ 07-0035, Section 7 of Supplement 1 |

| 17 | Plant-Wide Components | Hydrogen Tanks | See Appendix N of NUREG/CR-6850 | EPRI 1011989 / NUREG/CR-6850 |

| 18 | Plant-Wide Components | Junction Boxes | FAQ 13-0006 provides a definition for junction boxes that allows the characterization and quantification of junction box fire scenarios in plant fire compartment requiring detailed Fire PRA/Fire Modeling analysis and (2) describe a process for quantifying the risk associated with junction box fire scenarios in such plant locations. | FAQ 13-0006 |

| 19 | Plant-Wide Components | Miscellaneous Hydrogen Fires | See Appendix N of NUREG/CR-6850 | EPRI 1011989 / NUREG/CR-6850 |

| 20 | Plant-Wide Components | Off-gas/H2 Recombiner (BWR) | See Appendix N of NUREG/CR-6850 | EPRI 1011989 / NUREG/CR-6850 |

| 21 | Plant-Wide Components | Pumps and large hydraulic valves | The split fraction between pump electrical and oil fires is updated in EPRI 3002002936 / NUREG-2169 (0.69 electrical / 0.31 oil)

For electrical fires: Pumps (electrical fires) HRR Distribution (Case 6 of Table G-1) For oil spill split fractions, refer to the methods panel decision letter which updates the likelihood and oil spill sizes for general pump oil fires. For large hydraulic valves (which are included in Bin 21), the oil spill size fractions recommended in NUREG/CR-6850 should still be applied. For oil fires: See Section G.4 of NUREG/CR-6850 for HRR for flammable liquid fires. EPRI 3002005303, although not formally reviewed by the NRC, provides a method to more realistically characterize the HRR profile and duration for liquid spill fires. |

EPRI 3002002936 / NUREG-2169 |

| 22 | Plant-Wide Components | RPS MG Sets | Use HRR distribution for Electric Motors (Case 7 of Table G-1) | EPRI 1011989 / NUREG/CR-6850 |

| 23a | Plant-Wide Components | Transformers (oil filled) | See Section G.4 of NUREG/CR-6850 for HRR for flammable liquid fires. EPRI 3002005303, although not formally reviewed by the NRC, provides a method to more realistically characterize the HRR profile and duration for liquid spill fires. | EPRI 1011989 / NUREG/CR-6850 |

| 23b | Plant-Wide Components | Transformers (dry) | NUREG-2178 Volume 2 / EPRI 3002016052 provides updated HRR distributions for transformers (compared with the original distributions from NUREG-6850). | NUREG-2178 Vol 2 / EPRI 3002016052 |

| 24 | Plant-Wide Components | Transient fires caused by welding and cutting | (See Bin 3) | (See Bin 3) |

| 25 | Plant-Wide Components | Transients | (See Bin 3) | (See Bin 3) |

| 26 | Plant-Wide Components | Ventilation Subsystems | For electrical fires: Use HRR distribution for Electric Motors (Case 7 of Table G-1)

For oil fires: See Section G.4 of NUREG/CR-6850 for HRR for flammable liquid fires. EPRI 3002005303, although not formally reviewed by the NRC, provides a method to more realistically characterize the HRR profile and duration for liquid spill fires. |

EPRI 1011989 / NUREG/CR-6850 |

| 27 | Transformer Yard | Transformer - Catastrophic | The catastrophic failure of a large transformer is defined as an energetic failures of the transformer that includes a rupture of the transformer tank, oil spill, and burning oil splattered a distance from the transformer. The analyst should use the frequency and 1.) determine availability of offsite power based on the function of the transformer(s) and 2.) consider propagation to adjacent (not nearby) buildings or components. A propagation path may be considered at the location of open or sealed penetrations, e.g., where a bus-duct enters from the Yard into the Turbine Building. Structural damage need only be considered only where appropriate shields are not present to protected structures and components against blast or debris. | EPRI 1011989 / NUREG/CR-6850 |

| 28 | Transformer Yard | Transformer - Non Catastrophic | In this failure, oil does not spill outside the transformer tank and the fire does not necessarily propagate beyond the fire source transformer. Analyst can use all the frequency and assume total loss of the "Transformer/ Switch Yard" or may split this frequency equally among the large transformers of the area and assume loss of each transformer separately. Loss of offsite power should be determined based on the function of the affected transformer(s). | EPRI 1011989 / NUREG/CR-6850 |

| 29 | Transformer Yard | Yard Transformers (Others) | In the screening phase of the project, the analyst may conservatively assign the same frequency to all of the items in this group. If the scenario would not screen out, the frequency may then be divided among the various items in this group. A relative ranking scheme may be used for this purpose. The ranking may be based on the relative characteristics of the item and the analysts' judgment. | EPRI 1011989 / NUREG/CR-6850 |

| 30 | Turbine Building | Boiler | See Section G.4 of NUREG/CR-6850 for HRR for flammable liquid fires. EPRI 3002005303, although not formally reviewed by the NRC, provides a method to more realistically characterize the HRR profile and duration for liquid spill fires. | EPRI 1011989 / NUREG/CR-6850 |

| 31 | Turbine Building | Cable fires caused by welding and cutting | FAQ 13-0005 provides additional guidance for detailed fire modeling on both self-ignited cable fires and cable fires caused by welding and cutting. This FAQ outlines a more realistic approach for addressing these types of fires in cable trays and suggests replacement text for Section R.1 of NUREG/CR-6850. However, the current method of evaluating cable fire risk in NUREG/CR-6850 remains an acceptable approach. | EPRI 1011989 / NUREG/CR-6850 |

| 32 | Turbine Building | Main Feedwater Pumps | For electrical fires: Pumps (electrical fires) HRR Distribution (Case 6 of Table G-1)

For oil fires: FAQ 08-0044 (Section 9 of NUREG/CR-6850 Supplement 1) clarifies the severity factors for small fires (0.966 for a leak that impacts the pump), large fires (0.0306 for 10% inventory spill), and very large fires (0.0034 for 100% inventory spill). See Section G.4 of NUREG/CR-6850 for HRR for flammable liquid fires. EPRI 3002005303, although not formally reviewed by the NRC, provides a method to more realistically characterize the HRR profile and duration for liquid spill fires. |

EPRI 1011989 / NUREG/CR-6850 |

| 33 | Turbine Building | Turbine Generator Excitor | Appendix O (Section O.2.1 & Table O-2) recommends assuming the excitor fire is limited to the excitor itself. | EPRI 1011989 / NUREG/CR-6850 |

| 34 | Turbine Building | Turbine Generator Hydrogen | Appendix O (Section O.2.2 & Table O-2) provides guidance for both limited and severe T/G Hydrogen fires. Table O-2 also provides a conditional probability for a catastrophic T/G fire involving the hydrogen, oil and blade ejection. | EPRI 1011989 / NUREG/CR-6850 |

| 35 | Turbine Building | Turbine Generator Oil | Appendix O (Section O.2.3 & Table O-2) provides guidance for both limited and severe T/G oil fires. Table O-2 also provides a conditional probability for a catastrophic T/G fire involving the hydrogen, oil and blade ejection. | EPRI 1011989 / NUREG/CR-6850 |

| 36 | Turbine Building | Transient fires caused by welding and cutting | (See Bin 3) | (See Bin 3) |

| 37 | Turbine Building | Transients | (See Bin 3) | (See Bin 3) |

Recommended HRR Values for Electrical Fires

Legend for Fuel Type:

TS: Thermoset

TP: Thermoplastic

QTP: Qualified Thermoplastic

SIS: Synthetic Insulated Switchboard Wire or XLPE-Insulated Conductor

|

Enclosure Class/Function Group |

Enclosure Ventilation (Open or Closed Doors) |

Fuel Type* (TS/QTP/SIS or TP Cables) |

Gamma Distribution Characteristics |

|||||||||||

|

(a) Default |

(b) Low Fuel Loading |

(c) Very Low Fuel Loading |

||||||||||||

|

Alpha |

Beta |

75th Percentile (kW) |

98th Percentile (kW) |

Alpha |

Beta |

75th Percentile (kW) |

98th Percentile (kW) |

Alpha |

Beta |

75th Percentile (kW) |

98th Percentile (kW) |

|||

|

1 - Switchgear and Load Centers |

Closed |

TS/QTP/SIS |

0.32 |

79 |

30 |

170 |

|

|||||||

|

Closed |

TP |

0.99 |

44 |

60 |

170 |

|

||||||||

|

2 - MCCs and Battery Chargers |

Closed |

TS/QTP/SIS |

0.36 |

57 |

25 |

130 |

|

|||||||

|

Closed |

TP |

1.21 |

30 |

50 |

130 |

NOT APPLICABLE |

||||||||

|

3 - Power Inverters |

Closed |

TS/QTP/SIS |

0.23 |

111 |

25 |

200 |

|

|||||||

|

Closed |

TP |

0.52 |

73 |

50 |

200 |

|

||||||||

|

4a - Large Enclosures [>1.42 m3 (>50 ft3)] |

Closed |

TS/QTP/SIS |

0.23 |

223 |

50 |

400 |

0.23 |

111 |

25 |

200 |

0.38 |

32 |

15 |

75 |

|

Closed |

TP |

0.52 |

145 |

100 |

400 |

0.52 |

73 |

50 |

200 |

0.88 |

21 |

25 |

75 |

|

|

Open |

TS/QTP/SIS |

0.26 |

365 |

100 |

700 |

0.26 |

182 |

50 |

350 |

0.38 |

32 |

15 |

75 |

|

|

Open |

TP |

0.38 |

428 |

200 |

1000 |

0.38 |

214 |

100 |

500 |

0.88 |

21 |

25 |

75 |

|

|

4b - Medium Enclosures [≤1.42 m3 (50 ft3)] and > 0.34 m3 (12 ft3) |

Closed |

TS/QTP/SIS |

0.23 |

111 |

25 |

200 |

0.27 |

51 |

15 |

100 |

0.88 |

12 |

15 |

45 |

|

Closed |

TP |

0.52 |

73 |

50 |

200 |

0.52 |

36 |

25 |

100 |

0.88 |

12 |

15 |

45 |

|

|

Open |

TS/QTP/SIS |

0.23 |

182 |

40 |

325 |

0.19 |

92 |

15 |

150 |

0.88 |

12 |

15 |

45 |

|

|

Open |

TP |

0.51 |

119 |

80 |

325 |

0.30 |

72 |

25 |

150 |

0.88 |

12 |

15 |

45 |

|

|

4c - Small

Enclosures |

Not Applicable |

All |

0.88 |

12 |

15 |

45 |

NOT APPLICABLE |

|||||||

|

Vertical cabinets, one cable bundle |

Closed |

TS/QTP/SIS |

0.84 |

59.3 |

69 |

211 |

NOT APPLICABLE |

|||||||

|

Closed |

TP |

1.6 |

41.5 |

90 |

211 |

|||||||||

|

Vertical cabinets, more than one cable bundle |

Closed |

TS/QTP/SIS |

0.7 |

216 |

211 |

702 |

NOT APPLICABLE |

|||||||

|

Closed |

TP |

2.6 |

67.8 |

232 |

464 |

|||||||||

|

Open |

TP |

0.46 |

386 |

232 |

1002 |

|||||||||

|

Pumps (electrical fires) |

N/A |

N/A |

0.84 |

59.3 |

69 |

211 |

NOT APPLICABLE |

|||||||

|

Motors |

N/A |

N/A |

2.0 |

11.7 |

32 |

69 |

NOT APPLICABLE |

|||||||

|

Transient Combustibles |

N/A |

N/A |

1.8 |

57.4 |

142 |

317 |

NOT APPLICABLE |

|||||||

Additional Fire Modeling Considerations

High Energy Arching Fault (HEAF) Research

EPRI is currently performing additional research on the risk impact of HEAF events, for example the impact of aluminum conductors. A 2019 report EPRI 3002015992 provides an overview of nuclear power station electrical distribution systems and covers fault protection system concepts, fault isolation times, the potential impact of HEAFs on Class 1E electrical distribution systems, and typical industry practices and programs that help ensure proper operation. This report also provides some preliminary risk insights based on a review of existing data.

Heat Soak Models

NUREG/CR-6850 Appendix H (Section H.1.5.2) provides an empirical approach for calculating the time to electrical failure of cables.

NUREG/CR-6931 Volume 3 documents the THIEF model, which is a one-dimensional heat conduction model into a cylinder for predicting the internal temperature of cables subjected to fire generated conditions. The document also provides verification and validation material for the model. The validation information is based on the CAROLFIRE experiments for investigating electrical shorts in cables, which also collected cable surface and internal temperature information. Using the THIEF model, temperature predictions can be obtain considering cables in conduits and having different jacket and insulation material.

Location Factor

When the fire is located near a wall or in a corner, less air can be entrained into the fire plume. Less air entrainment into the fire plume produces higher plume temperatures. The flames from fires in contact with wall and corner surfaces tend to be longer, also resulting in higher plume temperatures. For such fires, a location factor, traditionally 2 for fires near a wall or 4 for fires near a corner, has been applied as a correction to the plume temperature calculation. NUREG-2178 Volume 2 / EPRI 3002016052 Section 6 demonstrates that the traditional approach is overly conservative, and presents new factors of 1 for all wall configurations and either 4, 2, or 1 for corner configurations depending on the distance (4 for a distance of 0-1 ft., 2 for 1-2 ft., and 1 for all distances greater than 2 ft.).

Fire Propagation and Suppression Guidance

Detection-Suppression Event Tree

Section 5 of NUREG-2230 / EPRI 3002016051 presents a revised detection-suppression event tree model for characterizing fire detection and suppression activities in response to a fire event (revised compared with the original model described in Appendix P of NUREG/CR-6850 and Chapter 14 of NUREG/CR-6850 Supplement 1). This modification is intended to capture the potential for plant personnel suppression during the early stages of a fire.

Fire Damage Criteria

Cable Damage Criteria

FAQ 16-0011 provides radiant heating and temperature criteria for bulk cable tray ignition (which was not previously provided in NUREG/CR-6850. The bounding cable damage and ignition criteria remain the same. A summary of the results are shown below. The analyst should refer to both NUREG/CR-6850 Appendix H and FAQ 16-0011 for full guidance.

| Bounding Cable Damage / Ignition Criteria | Bulk Cable / Tray Ignition Criteria | |||

|---|---|---|---|---|

| Cable Type | Radiant Heating | Temperature | Radiant Heating | Temperature |

| Thermoplastic | 6 kW/m2 | 205°C | 25 kW/m2 | 500°C |

| Thermoset | 11 kW/m2 | 330°C | ||

For Kerite cables, refer to NUREG/CR-7102 for damage criteria. Originally FAQ 08-0053 was initiated to clarify failure thresholds for Kerite cables and the resolution can be found in the closure memo dated June 6, 2012 following the publication of NUREG/CR-7102.

Treatment of Sensitive Electronics

FAQ 13-0004 provides supplemental guidance for the application of the lower damage thresholds provided in NUREG/CR-6850 Section 8.5.1.2 and H.2 for solid-state components. Fire Dynamics Simulator (FDS) modeling results support the recommendation that a generic screening heat flux damage threshold for thermoset cables, as observed on the outer surface of the cabinet, can be used as a conservative surrogate for assessing the potential for thermal damage to solid-state and sensitive electronics within an electrical panel (cabinet). Since the conclusions of the FDS analysis are based on heat flux exposure to the cabinet, the 65°C temperature damage criterion must still be assessed for other types of fire exposures to the enclosed sensitive electronics.

Cable Tray Fire Propagation

FAQ 08-0049, Section 11 of Supplement 1 clarifies the limits of the empirical cable tray fire propagation model in EPRI 1011989, NUREG/CR-6850. The model can lead to conservative estimates of cable fire growth rates and unrealistically short room burnout times when used outside the Zone of Influence (ZOI)—i.e., outside the fire plume that extends above the ignition source.

NUREG/CR-7010 documents the results of experiments to better understand and quantify the burning characteristics of grouped electrical cables commonly found in nuclear power plants. Volume 1 studies horizontal cable trays and Volume 2 studies vertical shafts and corridors. The experiments in Volume 1 address horizontal, ladder-back trays filled with unshielded cables in open configurations. The results of the full-scale experiments have been used to validate a simple model called FLASH-CAT (Flame Spread over Horizontal Cable Trays). The document also provides verification and validation material for the FLASH-CAT model. Volume 2 performed experiments on vertical cable tray configurations and enclosure effects. Volume 2 also extends the FLASH-CAT model to address cable trays within enclosures and vertical tray configurations.

Manual Non-Suppression Probability Estimates

- NUREG-2169 EPRI 3002002936 provides updated manual non-suppression probability data through the year 2010. The manual NSPs documented in FAQ 08-0050 (NUREG/CR-6850 Supplement 1 Chapter 14) do not contain the latest NSP estimates.

- FAQ 17-0013 provides an update to the HEAF suppression curve (beyond that provided in NUREG-2169)

| Calculation Source Document | Suppression Curve | Number of Events in Curve | Total Duration (minutes) | Rate of Fire Suppressed (λ) | |||

|---|---|---|---|---|---|---|---|

| Mean | 5th Percent | 50th Percent | 95th Percent | ||||

| NUREG-2169 | Turbine-generator fires | 30 | 1167 | 0.026 | 0.019 | 0.025 | 0.034 |

| NUREG-2178, Vol. II | Control room | 10 | 26 | 0.385 | 0.209 | 0.372 | 0.604 |

| NUREG-2169 | Pressurized water reactor containment (at power) | 3 | 40 | 0.075 | 0.020 | 0.067 | 0.157 |

| NUREG-2169 | Containment (low power-shutdown) | 31 | 299 | 0.104 | 0.075 | 0.103 | 0.0136 |

| NUREG-2169 | Outdoor transformers | 24 | 928 | 0.026 | 0.018 | 0.026 | 0.035 |

| NUREG-2169 | Flammable gas | 8 | 234 | 0.034 | 0.017 | 0.033 | 0.056 |

| NUREG-2169 | Oil fires | 50 | 562 | 0.089 | 0.069 | 0.088 | 0.111 |

| NUREG-2169 | Cable fires | 4 | 29 | 0.138 | 0.047 | 0.127 | 0.267 |

| NUREG-2230 | Electrical fires* | 74 | 653 | 0.113 | 0.093 | 0.113 | 0.136 |

| NUREG-2230 | Interruptible fires (Bin 15) | 43 | 288 | 0.149 | 0.114 | 0.148 | 0.189 |

| NUREG-2230 | Growing fires (Bin 15) | 18 | 179.5 | 0.100 | 0.065 | 0.098 | 0.142 |

| NUREG-2169 | Welding fires | 52 | 484 | 0.107 | 0.084 | 0.107 | 0.133 |

| NUREG-2169 | Transient fires | 43 | 386 | 0.111 | 0.085 | 0.111 | 0.141 |

| FAQ 17-0013 | HEAFs | 8 | 602 | 0.013 | 0.007 | 0.013 | 0.022 |

| NUREG-2169, NUREG-2230 | All fires | 398 | 5878 | 0.068 | 0.062 | 0.068 | 0.073 |

| * Electrical fire include non-cabinet electrical sources, such as electrical motors, indoor transformers, and junction boxes, among other electrical equipment. | |||||||

Incipient Detection

NUREG-2180 NRC guidance on crediting incipient detection systems in fire PRA is discussed in NUREG-2180. The issuance of NUREG-2180 retires FAQ 08-0046 (Chapter 13 of NUREG/CR-6850 Supplement 1) as documented in the July 1, 2016 letter to NEI.